Manufacturing & Development Blog

Design Revision to make Installation Easier

Date: 5 / 18 / 23

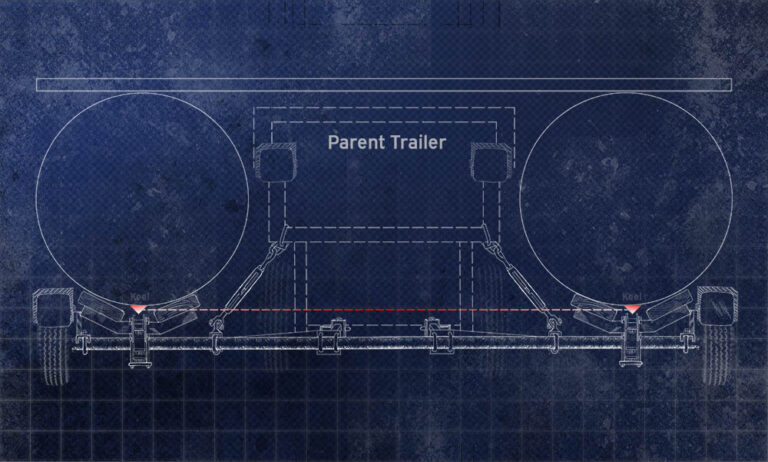

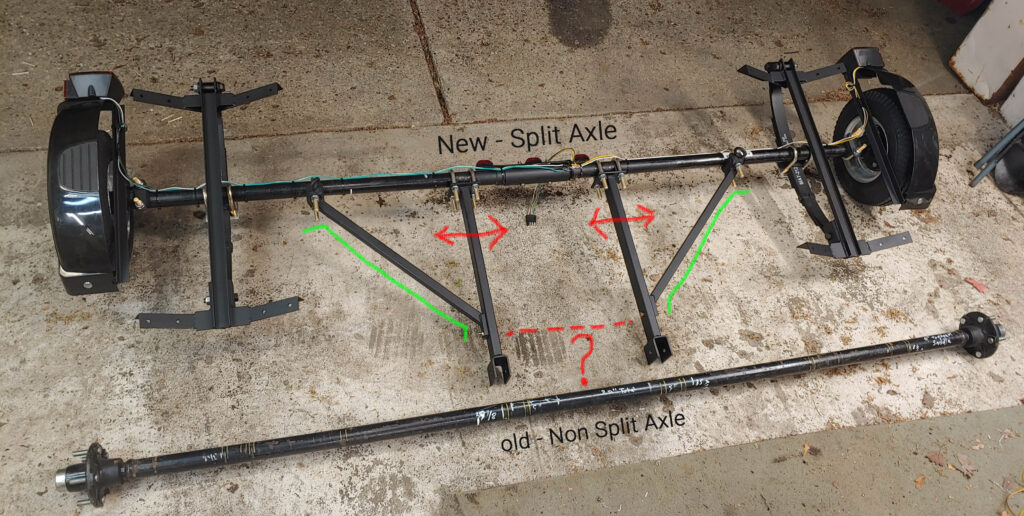

The Axle Connector Arms for Most of development were designed under the theory that they ought to be adjustable in order to ensure they were as wide as possible for maximum support. After intentionally hitting several curbs to test the strength of the axle axle, we did managed to bend an axle. Soon after that 45° Braces were added to the design to significantly strengthen the Axle.

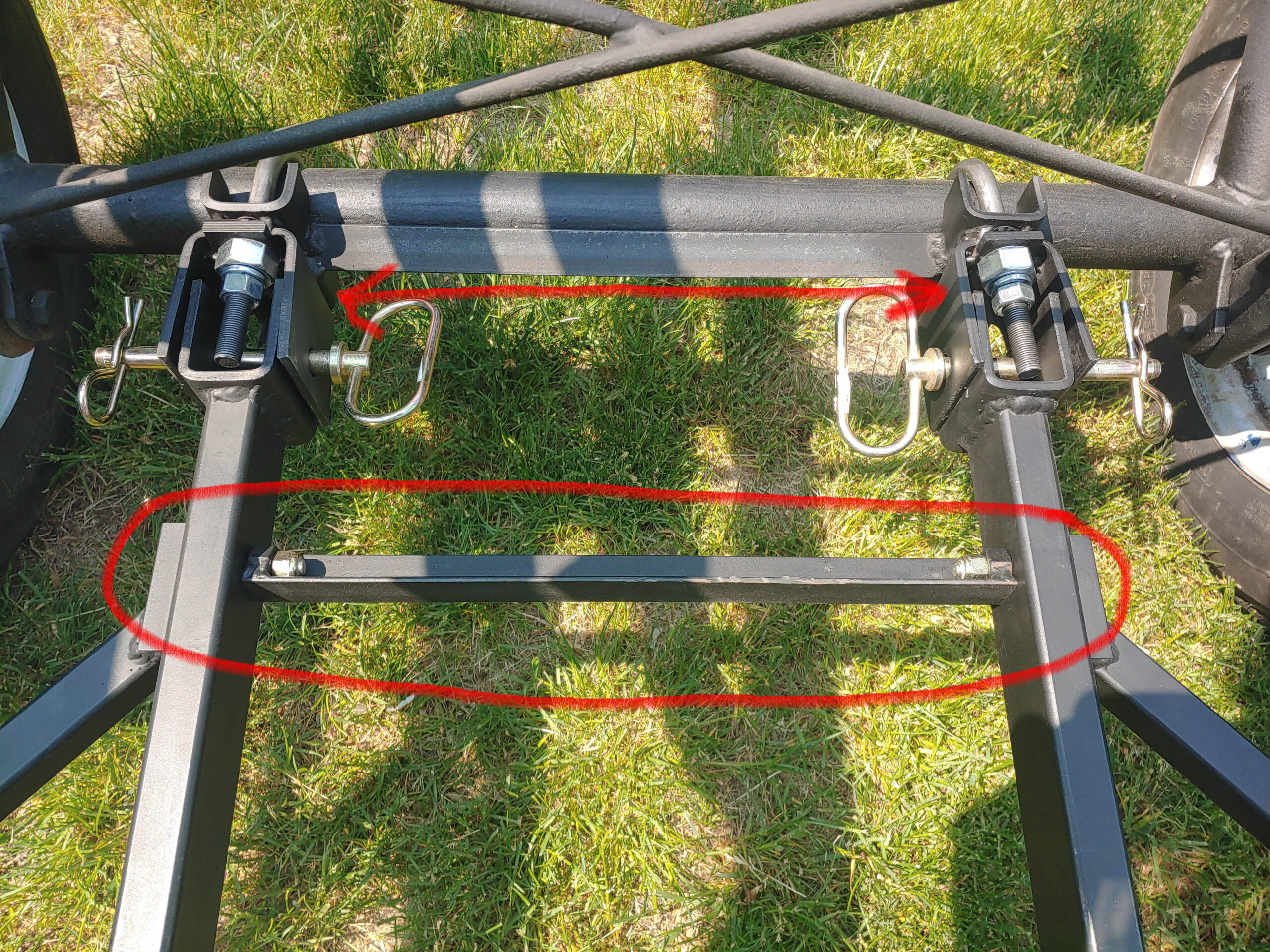

Now in the last week or so, after reviewing the installation process, the theory that these arms need to adjustable was re-considered and let go. We added a brace to make the distance between the arms fixed, this nets an easier install and a stronger product. The Axle Brackets are also now a fixed distance & have moved towards a more universal fit. But more on that in a different post.

Website Launched!

Date: 4 / 08 / 23

After a kick in the pants from the Almighty & 2 years of Hard work. . .

We Are Now Taking Orders!! ^^ This Website Went Live on April 8th 2023

We are building a first initial Production Run of 12 Units.

We plan to Start Shipping By 4th Week of April!

After a kick in the pants from the Almighty & 2 years of Hard work. . . We Are Now Taking Orders!! ^^ This Website Went Live on April 8th 2023 We are building a first initial Production Run of 12 Units. We Plan to Start Shipping by the 4th Week of April!

Chopped The Axle In Half

Date: 2 / 28 / 23

During most of development, I thought I could ship the full size, 102″ axle without much added cost. Turns out, most shipping company’s have huge upcharges for any item over 8ft long (96″). So, I decided to chop the axle in half for significantly cheaper shipping. To re-attach the axle together I built a sleeve to fit over the axle that uses a bolt with a nylock nut to lock it in place.